What issue can we solve for you?

Type in your prompt above or try one of these suggestions

Suggested Prompt

Insights

How Online Grocers Can Win and Retain More Customers

How Online Grocers Can Win and Retain More Customers

During the height of the pandemic, grocers managed an unprecedented influx of online orders for delivery and pickup, or click and collect. At the time, this influx presented grocers with challenges like too few time slots for orders, not enough products and the inability to recruit enough pickers and drivers to handle the demand.

Today, the challenges faced by online grocers have evolved. Many people are shopping in-store again, so there is less strain on delivery and click and collect services. However, competition is steep, making meeting and exceeding customer expectations essential.

Consumer data reveals top pain points

Publicis Sapient reviewed the performance of U.K. and French e-commerce grocers. The research reveals that shoppers have three main expectations for online grocery shopping. These standards are universal:

- Did I get my entire order with no substitutions or missing items?

- Do my fresh items have a decent shelf life?

- Did I have a great delivery or pickup experience?

The verdict? Many consumers aren’t satisfied with the current level of service (see Figure 1). And the truth is, these sub-par experiences are the main drivers of churn (see Figure 2). While customers’ tolerance of these issues was high due to a lack of options during the pandemic, it is no longer the case today.

Figure 1: Top reasons for customer churn in online grocery shopping

Figure 2: Top three delivery challenges for online grocers

Figure 2: Top three delivery challenges for online grocers

Meeting shopper expectations is one of the most pressing imperatives for online grocers today and a critical path forward to reduce churn, delight customers and improve online profitability. Here’s how grocery retailers can address delivery and pickup issues.

Challenge 1: How can online grocers improve order accuracy?

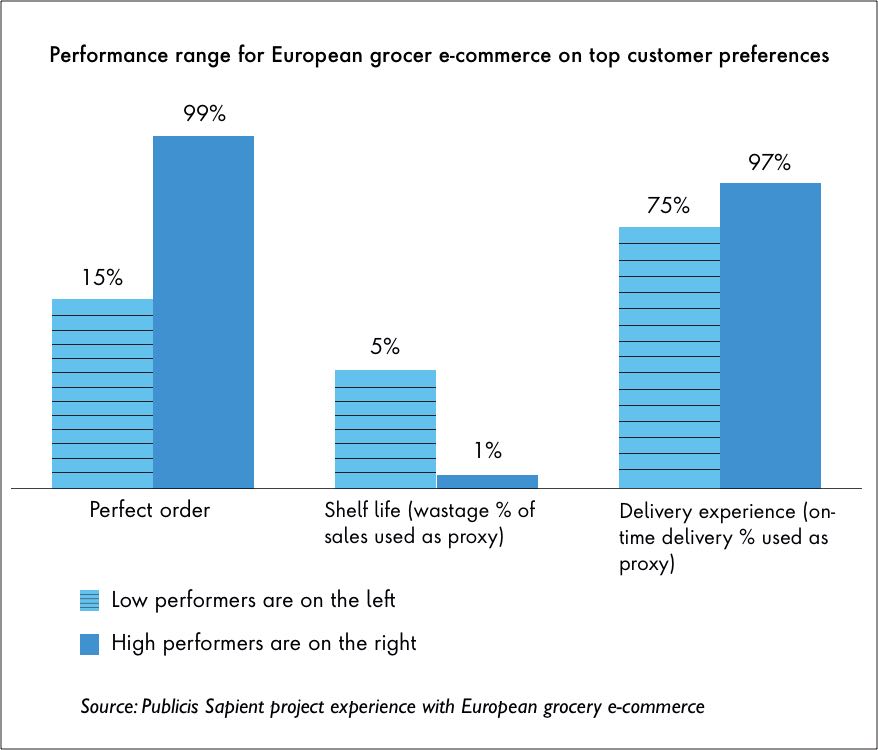

Consumers want perfect orders without missing items or substitutions. We have seen retailers with staggeringly low perfect order rates hovering at 20 percent during set periods. Best-in-class is around 95 percent when picking up orders at customer fulfillment centers (CFC) and about 66 percent for in-store pickup.

One issue that leads to customer frustration regarding missing items is the visibility of in-stock products several days or hours before the actual picking and delivery date. This is also known as available-to-promise (ATP), a system that’s often not present on grocer websites. In the absence of a robust ATP, online grocers essentially offer products they cannot deliver. These products often include top sellers, items on promotion with limited quantities or those impacted by unusual demand patterns. This problem is particularly acute for retailers where products are picked by in-store shoppers and by online pickers combined with a lack of live inventory or no regular inventory refresh. When one or more items are missing, the average order value (AOV) and profitability of the overall order are negatively impacted.

Substitution algorithms are often not accurate enough or sufficiently personalized to individual customer tastes and preferences. They also often recommend more expensive items (e.g., a national brand equivalent when a private label is out of stock) to make up for missing items, causing grocers to disappoint customers and potentially affect margins.

Here are five ways grocers can improve order accuracy:

1. Enable a robust ATP system and algorithm. ATP is made up of three components: understanding the current inventory on hand, incoming supply and committed demand. ATP, therefore, can predict if a SKU will have available inventory at the point of pick. The e-commerce channel can consume this prediction through a real-time API and mark SKUs as “out of stock” depending on when the customer wants their order delivered.

2. Improve forecasting with better data and ordering systems. Online grocers can use a custom forecasting technique for online orders. The existing order backlog provides the starting point for a relatively accurate forecast after predicting future amendments by customers. New data sources can be used to predict the remaining orders that will arrive by the order cut-off date (e.g., items in basket but not checked out, slots booked, customer reorder rates or planned outbound marketing to existing customers).

3. Refresh inventory every 15 minutes on the app/website. By using the ATP system developed, multiple channels can receive a refresh of the predicted inventory of SKUs. The website can then delist SKUs if they are not expected to be restocked in time for the customer’s booked slot.

4. Optimize online product range to increase the availability of core lines. Grocers can focus their product range on high-performing SKUs that generate most of their sales and eliminate underperformers, enabling better supply chain performance on the remaining SKUs. Moreover, some SKUs that are highly duplicative to other SKUs, like smaller pack sizes or niche flavors, can be delisted to see if customers substitute to the alternative SKU. If grocers use substitutions, this data can be highly informative for understanding whether SKUs are treated similarly by customers and ripe for delisting.

5. Limit substitutions to improve forecast accuracy. By stopping substitutions altogether for problematic SKUs, grocers’ data sets will slowly be “cleaned,” allowing their forecasting and ordering algorithm to work better as true demand is accounted for.

Challenge 2: How can grocers improve produce shelf life?

Customer research tells us that shelf life at home, or lack of freshness, is the second most important predictor of customer churn.

In-store shoppers are accustomed to selecting items with the most extended expiration date (often stretching their arms to the back of the shelf). However, online shoppers often end up with products with a shorter fridge life, leading to lower satisfaction, food waste and a lower perception of value for the money. In the worst cases, some items arrive damaged, spoiled or otherwise unusable, generating complaints to customer service and refunds.

What can retailers do about it? The combination of the following activities enabled Publicis Sapient to help a grocer reduce wastage to less than one percent for previously problematic SKUs:

1. Minimize waste with storage techniques. Changing the layout to one shelf life date allocated per single shelf space for critical items and programming the pick system to pick on a “first-in, first-out” (FIFO) policy minimizes wastage and shelf life loss. For other non-critical items where there is not enough space for multiple dates, different storage techniques, like caged-off inventory or top-to-bottom stacking of crates, can be used to prevent “last-in, first-out.”

2. Minimize lead times between reception or picking by revising the inbound delivery schedule. Publicis Sapient helped create a more robust quality assurance (QA) process that acted as the last line of defense. It prevented visually spoiled items from being delivered, which reduced the rate of customer refunds.

3. Establish visual checks by a quality team for sensitive items. It is imperative to create a strong QA process that acts as the last line of defense for orders, checking for spoilage and ultimately reducing the rate of customer refunds requested.

Challenge 3: How can grocers improve the interaction experience between customers, associates and delivery drivers?

The third imperative grocers need to address is the fulfillment experience. This moment of order delivery (or pickup) requires shoppers to interact with another person. It can be a significant factor for converting otherwise neutral customers into promoters of a retailer. How friendly was the driver or store employee? Was the driver on time? Was there any conversation? Did the driver or store associate present any substitutions or help bring bags into the home or vehicle?

It became standard practice to leave bags at the front door during the pandemic, limiting human interaction and making it possible to move quickly to the next delivery. Today, in post-COVID times, retailers can take advantage of delivery as another touchpoint where they can provide a great experience.

In the case of delivery, the driver becomes the face of the brand. Many online grocers have not sufficiently invested in training their drivers in customer interactions. Instead, speed is prioritized to increase drops per route. A friendly delivery person equipped with a “script” can leave a far better impression that can strengthen customer relationships and loyalty. Taking a few minutes longer for an improved customer experience is often a worthwhile trade-off.

This approach also applies to click and collect, or curbside pickup. Customers are now less willing to accept a clunky experience, which can involve queuing for a long time. Publicis Sapient has helped design solutions flagging customers’ ETA or their geolocation on the premises of the grocer to help the staff prepare the order in advance, making the experience as smooth and quick as possible for the customers. For example, Publicis Sapient created a custom app for drivers that enhanced the algorithm used for allocating orders to routes, thus allowing the grocer to either increase dwell time or drops per route depending on the capacity utilization for that day.

The online grocery market is changing at an unprecedented speed. Providing shoppers with the exact items they ordered with the best shelf life in a timely and friendly fashion is becoming table stakes—and a prerequisite for retention and profitability.

Authors:

Thierry Elmalem

Senior Managing Director, Management Consulting, International

Marianna Avanyan

Senior Principal, Management Consulting, U.K.

Ming Tsai

Global Strategy Lead

Mathieu Larroumet

Managing Director, Management Consulting, France